News

Ultrasonic Rail Flaw Detector “Rail Tester” PRD-300

The new PRD-300 Rail Tester is the culmination of TOKYO KEIKI RAIL TECHNO’s more than 35 years of experience and knowhow in ultrasonic flaw inspection for railways.

The PRD-300 builds on its popular predecessor - the PRD-100 Series which is used extensively in railway inspection and maintenance - and represents a comprehensive model change with major enhancements including expanded functions.

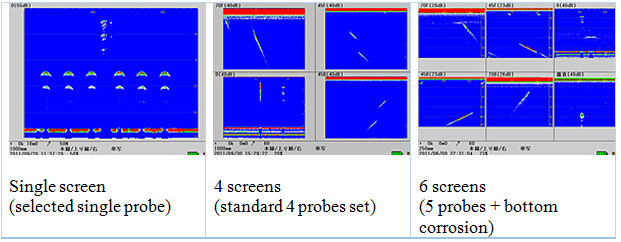

New multiple 4-screen and 6-screen displays

New probes composition

A new -70° probe option is available in addition to the standard 4-probe set of 0°, ±45° and +70° probes.

[ +70°, +45°, 0°, -45°, -70° ]

Detecting unit with 5-probe arrangement

Rail bottom zoom display function

A rail bottom zoom display function with the 0° vertical probe is standard equipment. This zoom display function can detect rail bottom corrosion due to electrolytic corrosion of rails inside tunnels and at crossings - pinpointing their location as well as providing quantitative data on the extent of corrosion.

Flaw images can be uploaded to office PCs

Flaw images that are stored in internal memory can be uploaded to office PCs by using USB flash memories. (Compared to the previous method which utilized images stored in the video recorder, image analysis is greatly simplified.)

Source: ETA

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM